Feature

Testing times: hypersonic R&D

Hypersonic technologies have been a long time in development. Helen Haxell-White reports.

Main image: A hypersonic sled travelling at 6,400ft per second during a US test. Credit: US DoD

Feature

Taking stock: Europe’s rearmament quest

Europe greases the wheels of ammunition production through innovation and coordination – but is it enough? John Hill reports.

A hypersonic sled travelling at 6,400ft per second during a US test. Credit: US DoD

Acapability that can travel continents in a matter of minutes, defying conventional defence systems with unparalleled speed; this is not science fiction, this is the reality of hypersonic weapons - vehicles that shatter the sound barrier five times over.

Yet, beneath the missile, an intense global race is underway to capitalise on this revolutionary technology. This has profound implications for both national security and industrial innovation; and it all starts at the testing stage which is predominantly in the United States.

Global Defence Technology delves into the significant strategic investments of advanced hypersonic development, evaluating the materials, testing ground, and facilities required to meet the next generation of weapons.

Investment imperative

The strategic imperative of hypersonics is underscored by recent, significant investment surges. This summer alone, two major players, the US and Japan, have signalled massive commitments to the field of hypersonics.

The US, with its heritage in hypersonic research dating back to the 1960s, is set to allocate an unprecedented $3.9bn to hypersonic weapons in its upcoming FY26 Defense Budget. This marks an increase from the $441m earmarked in the previous administration's FY24 budget, highlighting a renewed focus on deterrence and strategic posturing within the battlespace, with a significant portion being allocated to R&D and enhancing the industrial base.

The US is home to testing facilities which support nations like Japan and the UK with their hypersonic developments respectively, as well as its own.

Similarly, driven by evolving threats in the Asia-Pacific region, Tokyo's latest defence strategy (2025-2036) reveals Japan's intent to commit approximately $2.86bn to its own hypersonic capabilities.

Expanding and advancing robust hypersonic capabilities depends on substantial investment in effective test beds, which encompass advanced materials, highly specialised testing facilities, and supported by critical international collaboration.

Illustrating this commitment, Q2 2025 saw 233 successful static test runs for a hypersonic propulsion system at the NASA Langley Research Centre. While the full scope of these trials remains undisclosed, these tests are vital for data collection and replicated improvement.

A wedge test article undergoing trials in the US. Credit: USAF

Collaboration is also proving essential. The UK Ministry of Defence’s Team Hypersonics UK programme, a joint effort with the US Air Force Research Laboratory and the UK’s Defence Science and Technology Laboratory, recently completed these static tests as part of a collaborative trial.

This involved hundreds of tests across the full supersonic, greater than the speed of sound or Mach 1, to hypersonic Mach range, leveraging real-time data to optimise designs and enhance propulsive performance. Crucially, these trials verified the high-speed air-breathing engine's ability to power a cutting-edge hypersonic cruise missile concept during demonstration, paving the way for future UK system upgrades.

This complex and often iterative development process was captured by Rob McHenry, deputy director of the Defense Advanced Research Projects Agency (DARPA), who highlighted in an interview in June with the Mitchell Institute for Aerospace Studies, on how DARPA's rigorous testing and trialling of hypersonics have been instrumental in advancing these weapon systems.

A prime example is the US Department of Defense's (DoD) trials of the Hypersonic Test Vehicle (HTV) 1 and 2, conducted from 2010 to 2011. While these tests encountered failures, they yielded crucial data for subsequent technological development. As McHenry suggested, even with limited initial understanding, pushing a technology to its limits during the test phase can reveal vital insights for its future trajectory.

McHenry commented: “I think the HTV 2 flew for some ten seconds, before it exploded, which we then applauded as a huge success, because in those few tens of seconds, we collected the data that informed the aerodynamic models that have led to every hypersonic system since.”

Developmental challenges

However, the path to hypersonic readiness is fraught with significant bottlenecks. A critical challenge lies in establishing efficient and accessible testing infrastructure. Inadequate number of wind tunnel facilities in the US, for instance, lead to debilitating testing backlogs.

As former US Deputy Undersecretary for Defense, Research and Engineering, Mark Lewis, highlighted on a SpaceNews call in March this year, these backlogs in the US can stretch from six to a staggering 24 months.

Lewis emphasised the harsh reality: “If we don't have adequate wind tunnel facilities, then that gives us a log jam, a backlog in our ability to test our systems. [...] So solving that log jam by creating more facilities, I think, is absolutely essential as part of [the] supply chain solution, in order to deliver the numbers of hypersonic systems [required].”

This infrastructure congestion is more than an inconvenience; it means researchers cannot afford to extend crucial test slots, even when facing challenges or needing more data points, further delaying development and innovation.

The good news is that new facilities are emerging, with a widely reported new testing site in Texas - situated at the Ballistic Aero-Optics and Materials range at the state’s A&M University RELLIS campus - poised to help alleviate some of this pressure, specifically for hypersonic projectile testing.

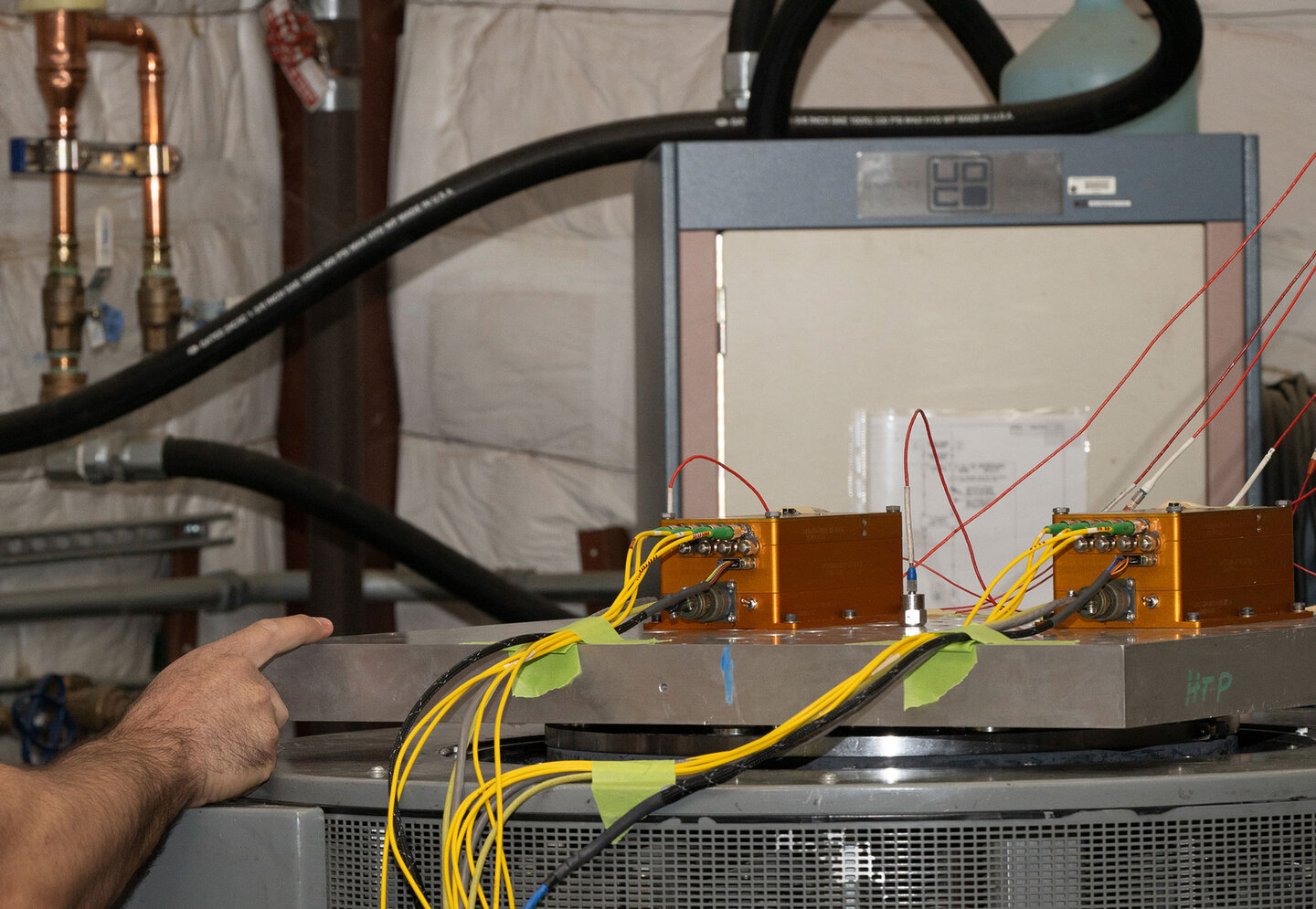

A Hypersonic Fibre Optic Sensing System being prepared for vibration tests. Credit: NASA / Jim Ross

Beyond infrastructure, the very physics of hypersonic flight presents a material science dilemma. As vehicles travel through the atmosphere at extreme speeds, air friction generates immense heat, necessitating a new generation of specialised high-temperature materials.

Lewis elaborated: “Hypersonic systems tend to operate at high temperatures. When you're flying at a high Mach number, you have friction with the air and you get hot. So, one of the driving requirements is surrounding the vehicle with high temperature material.”

Unlocking the full potential of hypersonics, particularly for advanced propulsion systems like scramjet engines, hinges on scaling additive manufacturing, such as 3D printing. This technology is pivotal because it enables the creation of the intricate internal cooling passages essential for managing the extreme heat generated during hypersonic flight.

As Lewis emphasised: “The supersonic combustion ramjet engines benefit tremendously from the application of additive manufacturing processes. The reason is that in order to build a scramjet, because scramjets get really hot, you want cooling in the walls.

“You want the fuel of the engine to be cooling the engine itself… you design it with these cooling flow passages. One of the best ways to do that is with additive manufacturing, where you're actually growing the walls of the engine.”

While additive manufacturing is key to lowering costs, the urgent requirement now is significant investment to expand these capabilities to meet future production demands at scale.

However, hypersonic investment faces a critical blockage at the testing stage, with inadequate R&D infrastructure to meet demands hindering innovation. The race to achieve speed is not just about the missile; it's a competition to overcome these R&D hurdles holding up development.

Potentially, SME's and non-prime industry alternatives, such as Australia's Hypersonix Launch Systems (see page 3), could offer a way to speed up development in being more able to iterate at the speed of relevance, a key topic across defence procurement circles.

Time will tell, but with Western countries and allies already behind the curve compared to Russia and China, there is very little of it to spare.

“That kind of decoupling is a lot more complicated than people would want to implement, and it's also a really expensive affair because it's not about just stopping the acquisition of new weapons. It's also about what you do with all of the training, the infrastructure, the planning for all of these contracts that are meant to last.”

Any breakup will also be painful for the US firms, which rely on partners to co-invest in research and systems development. The development and construction of F-35s is a project among allies, with components manufactured outside the US, including in Denmark and the United Kingdom.

“I think Lockheed Martin – as would the different subcontractors – would be very upset if there was any instability in the projected purchases of the F-35 from other countries,” said Bert Chapman, a professor at Purdue University and author of Global Defense Procurement and the F-35 Joint Strike Fighter.

I think the US can still step in, in a big way, to fill some of those gaps

Diane Zorri, academic director of Strategic Studies at Norwich University

Caption. Credit:

Phillip Day. Credit: Scotgold Resources

Total annual production

Australia could be one of the main beneficiaries of this dramatic increase in demand, where private companies and local governments alike are eager to expand the country’s nascent rare earths production. In 2021, Australia produced the fourth-most rare earths in the world. It’s total annual production of 19,958 tonnes remains significantly less than the mammoth 152,407 tonnes produced by China, but a dramatic improvement over the 1,995 tonnes produced domestically in 2011.

The dominance of China in the rare earths space has also encouraged other countries, notably the US, to look further afield for rare earth deposits to diversify their supply of the increasingly vital minerals. With the US eager to ringfence rare earth production within its allies as part of the Inflation Reduction Act, including potentially allowing the Department of Defense to invest in Australian rare earths, there could be an unexpected windfall for Australian rare earths producers.