Company Insight

Sponsored by Hypersonix Launch Systems

Hydrogen, Hypersonics and Homegrown Capability: The Hypersonix Formula

Smart and sustainable hypersonic tech, fast iteration, and a team that’s just as important as the IP.

Main image credit:

Australia’s Hypersonix Launch Systems is making Mach-speed waves in the global aerospace and defence sectors with its scramjet-powered, hydrogen-fuelled launch platforms. Its technology stack is built around SPARTAN, an air-breathing scramjet engine capable of speeds from Mach 5 to 12. From its “cheap and cheerful” DART AE demonstrator to ambitious reusable vehicles like VISR and Delta Velos, Hypersonix is targeting satellite launch, ISR, and hypersonic testing applications. We spoke with CEO Matt Hill and CTO Dr. Michael Smart about their technology roadmap, their role in the AUKUS Pillar 2 strategy, and why people are equally as important as technology for the stability, scalability and sustainability of Hypersonix.

With diesel vehicles accounting for 30% to 50% of greenhouse emissions at a mine site, replacing them with a battery-electric fleet is a sure way to drastically reduce overall CO2 emissions, but how else can mines benefit from this technology?

Leading underground manufacturers Normet believe the answer lies with SmartDrive. This architecture for battery electric vehicles (BEV) was developed in collaboration with customers, building on feedback, predicting future trends, and assessing the limitations of diesel engines, and comes with a wealth of benefits for operators.

Hypersonix is an incredibly innovative and sought-after company for partners right around the world, yet you’re also still a small and agile start-up. What do you credit this to?

Michael Smart: We really like the idea of defence being able to rely upon smaller, more agile companies, so what we're trying to do is build a bit of a small-business ecosystem in the high-speed drone and hydrogen economies in Australia.

One of the biggest areas of expertise that we need capability in is Ceramic Matrix Composites (CMC) manufacturing. We are always looking for partners who can help us do that. Two key 3D printing companies we work closely with are Amiga and Additive Engineering. We also collaborate with companies like Roo Technologies for mechanical design and build. These partners support us really well.

We work with universities too, mainly on research into new materials like CMCs. But what we really want is commercial companies that can manufacture components from these high-temperature composite materials. When we engage with universities, our focus is on translating that research into commercially viable activities. Historically, universities haven’t contributed as much as they could to commercial ventures or defence support. I’ve spent most of my career in academia, so I understand both sides — but it’s crucial that university knowledge be treated as a core part of technology development, not just pure research. That’s how we see the role of academia fitting into the broader ecosystem.

Matt Hill: I also want to emphasise that having a stable, inspired, and engaged team, particularly in the lead up to our first launch, cannot be understated. That’s what helps you to retain that IP and help build out that ecosystem. It’s important to nurture those people and keep them engaged by developing a good culture and having good management practices - we put a lot of effort into that.

Michael Smart: People talk about IP in a company, but there's so much knowledge in the staff, and when someone leaves, you can’t just extract it from them. So, it's critical if you want to develop cutting-edge technology that's ahead of the rest that you keep your staff.

Could you give us an introduction to your product family, and how they work together towards the end goal for Hypersonix?

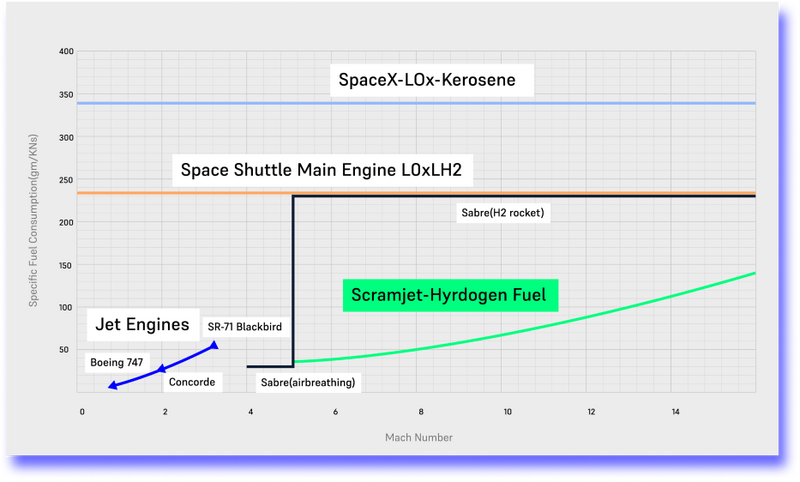

Michael Smart: Our long-term vision is to revolutionise access to space by flying satellites and other commercial or defence assets into orbit more like an aircraft, rather than a disposable rocket. The technology behind that is our SPARTAN scramjet engine. Because it uses atmospheric oxygen and hydrogen fuel, it doesn’t need to carry oxidiser like a rocket does, which makes it up to five times more efficient.

To get there, we’re taking a staged development approach. DART is our first real-world demonstrator. It’s a fully autonomous hypersonic aircraft that’s already gaining strong interest from defence in both Australia and the US. It’s “cheap and cheerful” in a way, but it’s highly functional, designed to prove out the scramjet and guidance technologies that will carry through to our next platform, VISR, and eventually to Delta Velos.

Delta Velos: Hypersonix’s reusable, hydrogen-powered launch vehicle designed for precision orbital delivery and aircraft-style landing.

In early June 2019, mining companies avoided increases to royalties by agreeing to provide A$70m to a A$100m infrastructure fund.

Frank Smith, Founder and CEO of TowHaul

Delta Velos is the endgame; a reusable, multi-stage launch vehicle that could take a satellite to space, deploy it with pinpoint orbital precision, and then return to land like a commercial airliner. We’re talking about a platform that could fly hundreds or even thousands of times, which completely changes the economics and responsiveness of satellite deployment.

How have you found the experience of scaling so far — not just on the technical side, but also from a manufacturing perspective, as you move from MVP to a reusable fleet?

Michael Smart: Right now, with DART, we’ve built our first airframe and we’re aiming to fly it later this year. A lot of the current work is in final integration and free-flight testing. If we can demonstrate reliable performance, we’re seeing strong interest already.

The next leap is producing a reusable hypersonic aircraft — something that can fly regularly, re-enter airspace safely, and land like a plane. That’s a much bigger challenge, and one where we are seeking partners to help us accelerate development and production.

DART: A three-metre, hydrogen-fuelled scramjet demonstrator and the world’s first fully 3D-printed high-temperature alloy hypersonic airframe. Powered by the SPARTAN engine, DART’s simple, scalable design enables rapid production, flexible launch options, and clean-burning, sustainable flight — all proudly designed and built in Australia.

Phillip Day. Credit: Scotgold Resources

From a small company perspective, speed is everything. We need to get functional products flying and in customers’ hands quickly, and that’s part of what defence departments actually like about working with us.

Sustainability, cost efficiency and cadence are central to what you’re doing, and those have kind of become the key differentiators in the launch sector. Have those traits become almost hygiene factors now if you want to attract partners?

Michael Smart: Yes, I think they are. There’s a big transition happening in the aviation industry; a shift away from fuels that produce CO₂. Hydrogen is the obvious answer, though batteries are in the mix too. The issue with batteries is they’re just too heavy for serious flight applications. Hydrogen, on the other hand, when you make it by splitting water, you’re putting energy into it, and you get that energy back when you burn it or use it in a fuel cell. In a sense, it’s like a very lightweight battery.

That’s why hydrogen makes so much sense for flight, and it’s why we see ourselves as part of that broader shift in aerospace.

SPARTAN combines green hydrogen fuel and full reusability to dramatically reduce the environmental impact of high-speed flight. In an industry known for waste, Hypersonix is proving that access to space doesn’t have to cost the Earth.

Hypersonics have become an important piece for the AUKUS Pillar 2 strategy. What is Hypersonix offering that makes it such a sought-after partner for the UK and US?

Matt Hill: First and foremost, we can do what we do at a fraction of the cost and time it would take a prime. We iterate fast, we develop fast, and we’re using scalable technology. Once we’ve vetted our 3D printing and supplier network, we will also be able to build across multiple sites, which is a big deal in this environment.

Then there’s the simplicity and utility of the platform. Right now, DART is being used primarily as a counter-hypersonics testbed — a way to test sensors, subsystems, or other tech at hypersonic speeds. There’s no shortage of demand for that capability. But what’s key is that every test flight generates data we feed back into our systems. That data helps us evolve each successive platform — from DART to VISR, and then Delta Velos.

Caption. Credit:

Ready to shape the future of hypersonic flight and sustainable space access?

Whether you're looking to collaborate on cutting-edge materials, test your tech at Mach speeds, or join a fast-moving ecosystem with global ambitions, Hypersonix is actively seeking partners and clients who share our vision. Contact us here.

Contact information

Hypersonix Launch Systems

Brisbane

2 Ron Boyle Crescent

Carole Park, QLD 4300

Australia

Web: www.hypersonix.com

- Biffa internal savings data, average saving (January - August 2023)

- Nisbets internal savings data, average saving (January – September 2023)

- Compliance365 internal data, average savings

- HEINEKEN UK data, Calculations based on SmartDispense® active accounts each year since 2015 with 10 lines

- Independent test results based on subterranean and ground floor pub cellars of varying sizes

- Independent test results based on subterranean and ground floor pub cellars of varying sizes