Company Insight

Sponsored by Omnetics Connector Corporation

The Return of Flex Circuit Connections for Rugged, High Density Electronics

A new breed of connector and cable increases rugged density in tomorrow’s electronic systems.

As more technology is being packed into high density electronic modules and devices our industry is dramatically embracing and expanding applications. Highly portable communication and tracking devices are becoming commonplace and autonomous robotic devices are being employed from military to recreation products. Drones are being used beyond their early use in photography to include multispectral imaging systems for geospatial mapping and LIDAR positions and ranging devices. Highly portable antenna systems are beginning to offer multiple beam frequencies and pulse amplitude sensing within the same units. Our concept and need for multiple sensors, data processing and transmission from small, light-weight portable systems is becoming insatiable.

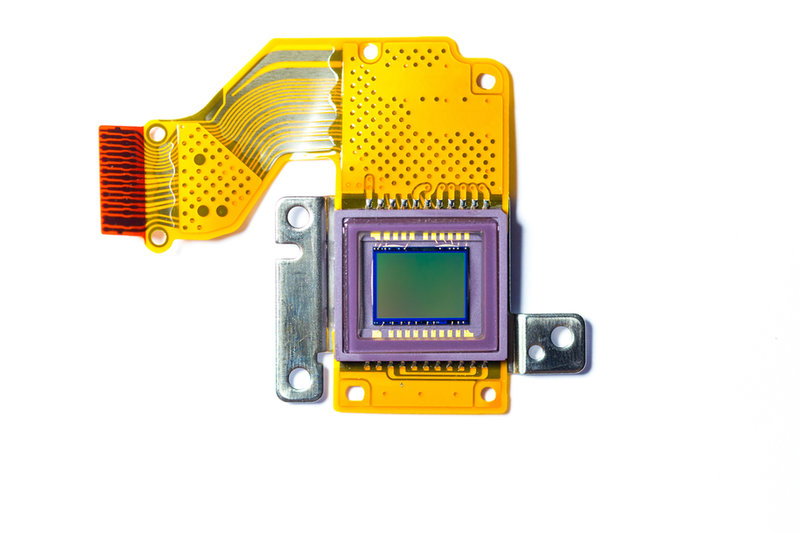

// PZN on Mini-Camera

Key to these technology expansions begins with new solid-state chip devices that function at significantly higher speeds and offer multiple functions within the same miniature chip and module design. As we moved from CMOS to GaNdigital processing and parallel processing circuitry, we developed simultaneous analog and digital signal processing that can analyze video camera images, convert that data to digital signals that are then transmitted onto micro-wave systems. As a result, processing speeds are doubling with larger image frames and the use of increased frame rates from 30 and 60 frames per second to over 100 frames per second. This is driving digital signal data rates from the, (older), 5 Gigabits/second to above 10 gigabits/second. To handle this rush for higher resolution simultaneously with higher speeds, new cable and connector designs are required to deliver quality signals to the image processor and storage systems. We are also including the use of infrared spectrum scanning and mixed light frequency monitoring. Soon we will see more use of hyperspectral imaging being applied in applications from food analysis to security scanning at airports. These multispectral imaging systems actually capture a cube-like structures of many wavelength frequency bands of image data that must be processed after collection. These systems will push the limits of high speed Ethernet processing systems as well as the interconnections serving them. Our portability is in direct contact with satellite constellations overhead to relay the new data around the globe to central information and military control centers. It is almost amazing that a satellite can receive and relay key data from a soldier on the battlefield to a drone and to a ship and to a central command system at once. Also amazing is that nearly simultaneously, the soldier is receiving communication, map imaging and strategic orders within moments of sending the data.

Above and beyond the call of duty

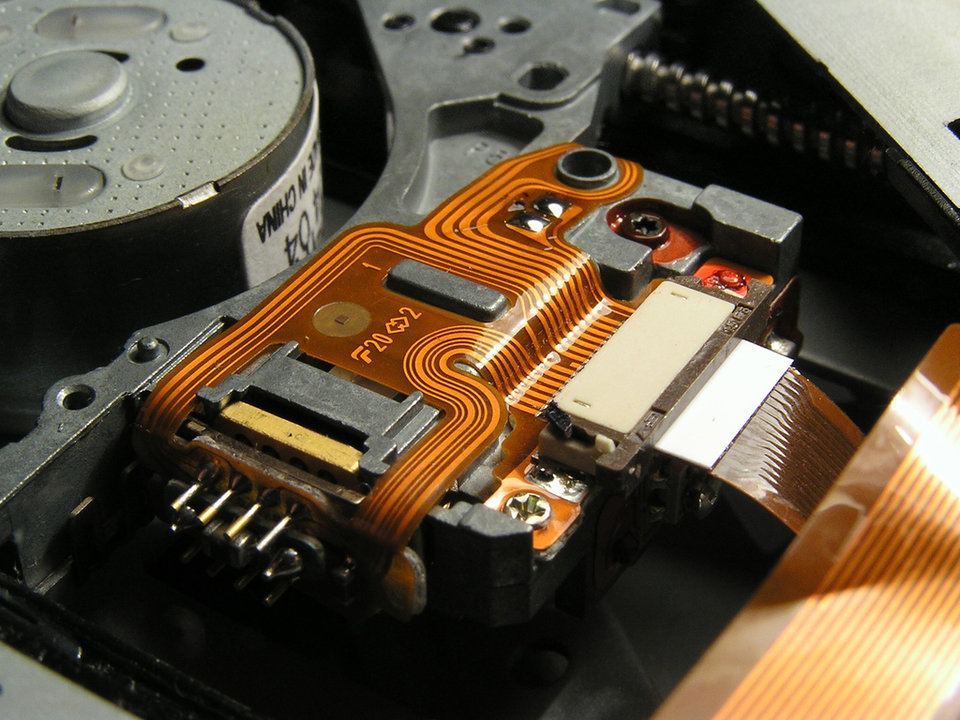

Flexible circuit design and manufacturing has been used for over 50 years for compact flexible interconnections and circuits crammed into small spaces. The materials for flexibility include a stack of a basic polymer film with a thin copper conducting layer bonded to it. Polymer and conductor layer thicknesses including selected properties are used to optimize the bend-ability, electrical conduction and ruggedness of the circuit. Circuit patterns, interconnection lines and bonding pads are designed and etched into the copper to match schematic needs. Line widths and spacing is often critical to assist signal propagation speeds, power dissipation and pad width for attaching components and connectors. In some cases, one or more layer of conductors are used with insulating polymer layers separating the circuits.

Meet today's tough data security compliance and exceed even the toughest government regulatory standards with kanguru.

This allows much higher density but must also consider signal crosstalk and noise coupling. Additions EMI shielding techniques are also applied in key areas to insure high signal integrity of the master frequencies. The more advanced flex circuit manufacturers offer high resolution and tight pattern control using a method called pattern-plate-up methods. Additional metal can be used to collect heat from mounted computer chips and drain that heat away from the circuit. Rugged, light-weight, high-density circuits have arrived for use in Cube Satellites to Myoelectric sensors that capture brain signals and relay them to newly adapted prosthetics on amputees. Smart circuits in automobiles route radar and surveillance control signals to retain lane control and avoid collisions.

Flex circuits are often mounted in key circuit processing areas and need power and signal and or sensor data routed to and from them to operate properly. This is achieved by extending the signal lines in flat-linear forms that can bend in-line with the signals. Using direct line routes and attending to bend radius rules the flex circuit is also a flat cable routing system to and from the remaining instrumentation. Note: that flat flexible circuit cabling has advantages over flattened ribbon wire cabling in many applications. Both have value but ribbon wire has multiple stranded wires within round extruded insulators. The round-multi-stranded wires within some cable can move during operation and cause difficulties such as inductive noise changes within the cable.

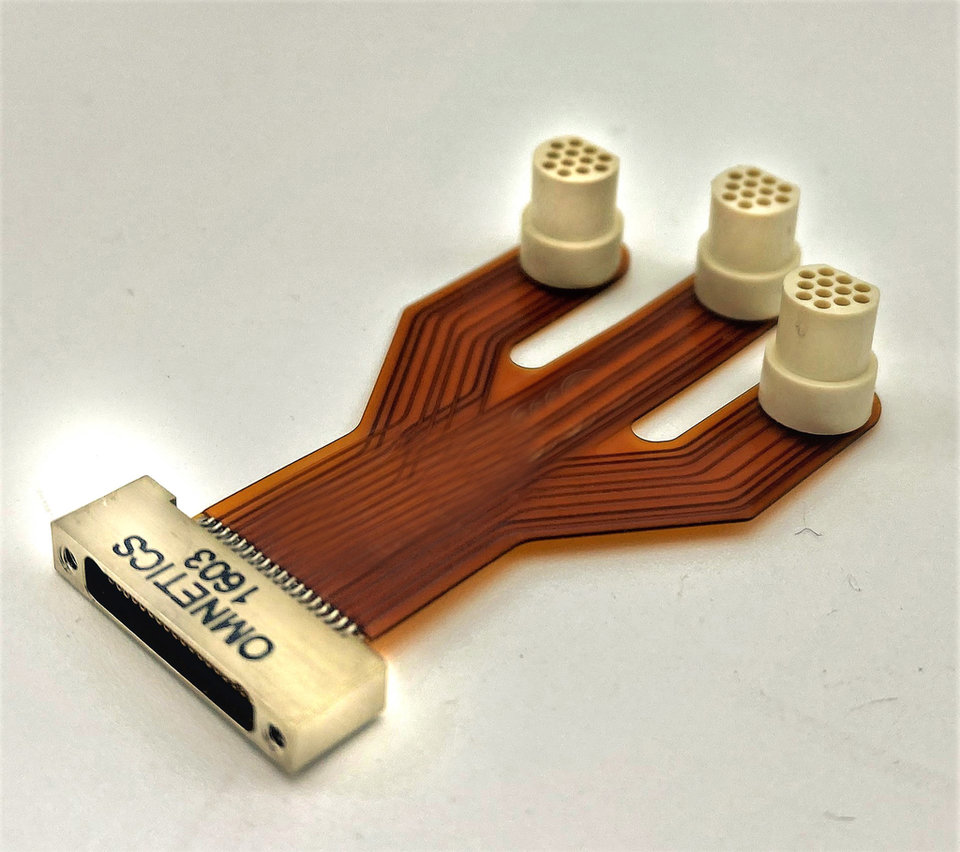

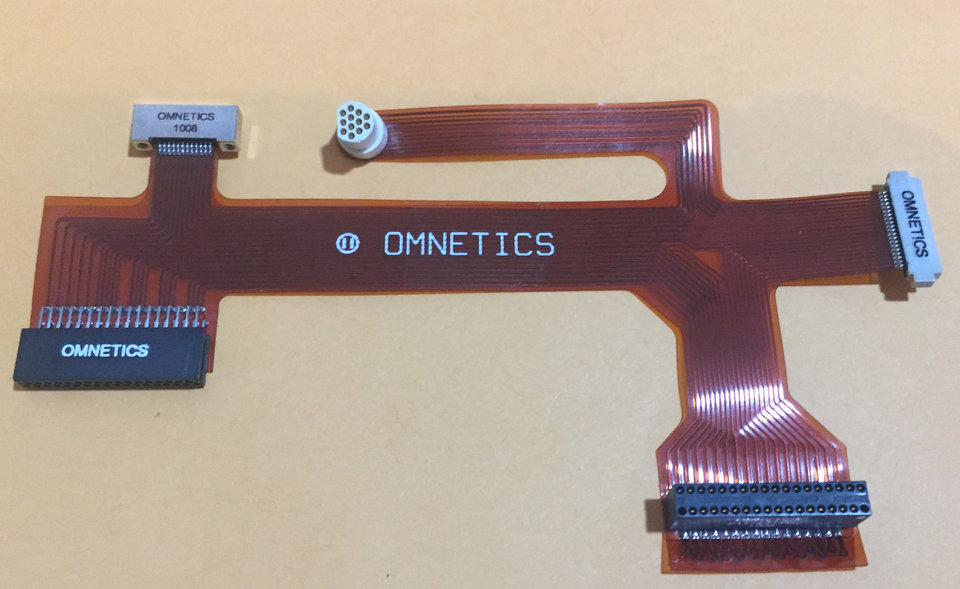

One of the most important parts of flex circuit use and interconnections includes the connector quality, match to the flexible circuit and its reliability in rugged high-density applications. Many commercial strip connectors used in home electronics are not designed for highly portable applications. Advanced circuits are often exposed to rather wide temperature ranges, physical shock and frequent mating and de-mating. Flexible circuit designers working in miniature circuitry often chose connector designs that have experience and passed military standard performance expectations previously. Examples include the Mil. Standard 83513 Micro-d connector with a pin to pin spacing of .050”, (1.27mm.) and or the Mil. Standard 32135 Nano-d connectors with pin spacing at .025”, (.635mm.). When very low profile strip connectors or edge card attachment connectors are needed, the more reliable strip connectors are built using military and space qualified materials that have proven performance in the military applications. One example of strip connector types used in space are those on Mars Rover that passed NASA Outgassing materials requirements and used military quality pin to socket mating system.

Flexible circuit designers have a wide range of high quality flex to connector options available. A key to success can be to select connectors that match both the physical and the more advance performance of today’s high sity electrical signal they are handling. Connector design suppliers have engineers available to work with system engineers to layout variations of connector to flex circuits using solid modeling on line. Selecting an existing connector to match flex routing lines can be done quickly. Quick turn customizing connectors somewhat standard today with advanced software and 3-d prototype machines to assure a rapid development and perfect fit as we are all seeing a rapid acceptance and need for higher density, rugged circuits that are increasing circuit speeds and running on much lower voltageand current levels. Using flexible circuit designs in place of wiring is also taking shape with designs for lower cost assembly in a high density impact circuits are also being done to help the design team achieve their goals rapidly and simply.