company insight sponsored by VPT

POWERING CRITICAL MISSIONS

VPT, INC. (VPT®) IS A GLOBAL LEADER IN PROVIDING DC-DC CONVERTERS AND EMI FILTERS FOR USE IN GLOBAL AEROSPACE, avionics, MILITARY AND INDUSTRIAL APPLICATIONS FOR THE RAPID DEVELOPMENT OF CRITICAL POWER SYSTEMS. FOR OVER TWO DECADES, VPT HAS ENGINEERED AND MANUFACTURED ITS PRODUCTS ACCORDING TO THE HIGHEST INDUSTRY STANDARDS, CARRYING MIL-PRF-38534 CLASS H AND CLASS K, ISO 9001, MANY OTHER FACILITY CERTIFICATIONS AND STRINGENT PRODUCT QUALIFICATIONS.

PROVEN HERITAGE IN A WIDE RANGE OF SOLUTIONS

VPT’s qualified products are available in a variety of feature offerings and screening levels to meet specific application needs. A complete, proven line of power modules and accessories satisfy a wide variety of avionics, military, high-reliability COTS, industrial and space application requirements.

Products include:

- DC-DC converters from 1 – 250 Watts

- Point of load converters from 3 – 20 Amps

- EMI filters

- Transient suppressors

- Inrush current limiters

- Bus converters

- Thermal pads

Table 1: Areal weight comparison of glass and ceramic – glass composite armour windows (available on the market)

Ideal for applications such as commercial and military aircraft and weapons systems, VPT’s isolated and non-isolated DV series of DC-DC converters save board space, weight, heat, and cost. With high efficiencies, wide temperature ranges, and U.S. DLA SMDs for most models, the DV series features power conversion products offering:

- 1-120+ watt power options

- MIL-PRF-38534 Class H

- -55 °C to +125 °C military temperature range, no power derating necessary

- 100% hermetic

- High efficiencies

- Thick-film hybrid technology for small size, light weight, and maximum reliability

- Built to military standards

- DLA SMDs available for most modules

- Products typically ship from stock

Table 1: Areal weight comparison of glass and ceramic – glass composite armour windows (available on the market)

VPT’s VXR Series for rugged military and commercial avionics applications is epoxy encapsulated with dual-sided thermal conduction and features a wide input voltage range (9 to 60 VDC). This patent-pending V-SHIELD® epoxy encapsulated packaging is highly resistant to chemical, solvent, and salt environments and is fully compatible with high-volume manufacturing processes including wave solder, cleaning solvents, high-pressure sprays, and aqueous wash.

With V-SHIELD® packaging, the DC-DC converter combines the reduced radiated emissions advantage of the metal packaging and the water/chemical resistivity of the epoxy packaging. Merging these two options provides a design with superior performance at a reasonable cost. V-SHIELD® packaging allows the converter to be used for multiple rugged applications, from military ground vehicles to commercial and military aircrafts. It can withstand harsh environments including severe vibration, shock and temperature cycling.

Products include:

- DC-DC converters from 1 – 250 Watts

- Point of load converters from 3 – 20 Amps

- EMI filters

- Transient suppressors

- Inrush current limiters

- Bus converters

- Thermal pad

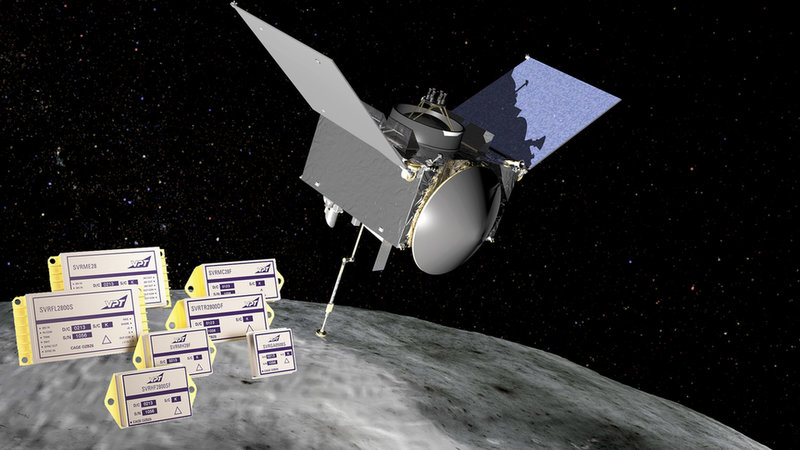

VPT also offers a range of DC-DC converters and accessories designed, tested, and proven for the challenging environment of space. The SVR series products feature maximum levels of radiation hardening with a Total Ionizing Dose (TID) of 100 krad(Si) and SEE of 85 MeV/mg/cm2. VPT’s SV series of products for space feature maximum levels of radiation tolerance with a TID of 60 krad(Si) and SEE of 44 MeV/mg/cm2. Both families of space products are based on space-proven heritage designs and available qualified to MIL-PRF-38534 Class K.

Table 1: Areal weight comparison of glass and ceramic – glass composite armour windows (available on the market)

Innovative Technology, Products and Services

VPT’s team is comprised of many of the most celebrated power supply innovators in the industry. VPT has pioneered numerous patents in power technology, and delivers those breakthrough technologies in field-proven power conversation products to satisfied customers.

For trusted power design assistance, VPT’s engineers partner with customers to ensure board efficiency and mission success.

Power innovations include:

- Complete magnetic feedback without optocouplers for long-term reliability

- Well controlled under-voltage lockout circuitry to eliminate slow startup

- V-SHIELD® epoxy packaging

- Lower high-frequency noise

Additional resources

VPT publishes helpful technical labs via its video channel to address the multitude of questions that arise when designing power systems for critical programs.

get in touch!

Global customers of VPT include NASA, Lockheed Martin, Boeing, Raytheon, ESA, Thales and General Dynamics. VPT is part of the HEICO Electronic Technologies Group (NYSE:HEI.A) (NYSE:HEI).

More information can be found at:

www.vptpower.com

Go to top